Caractéristiques et avantages

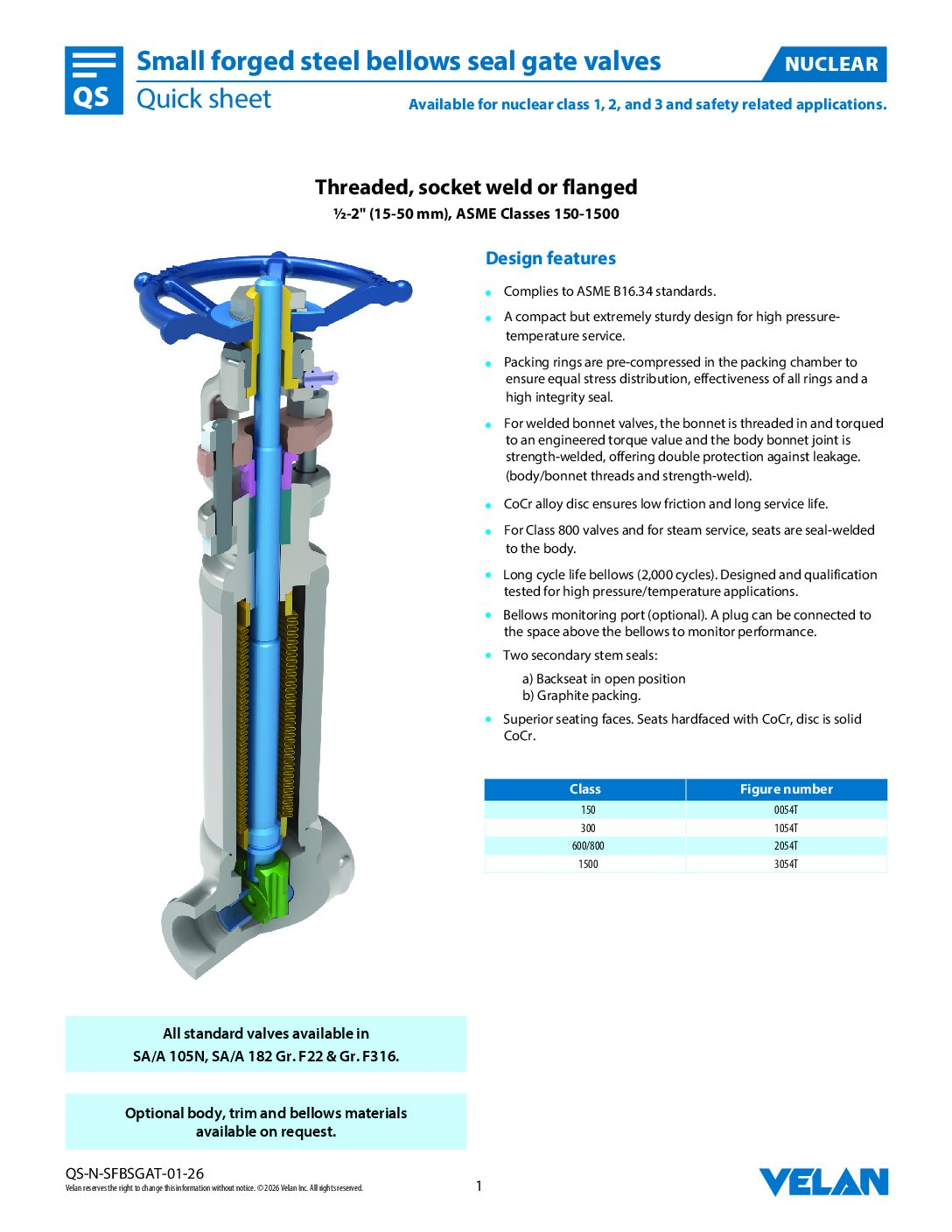

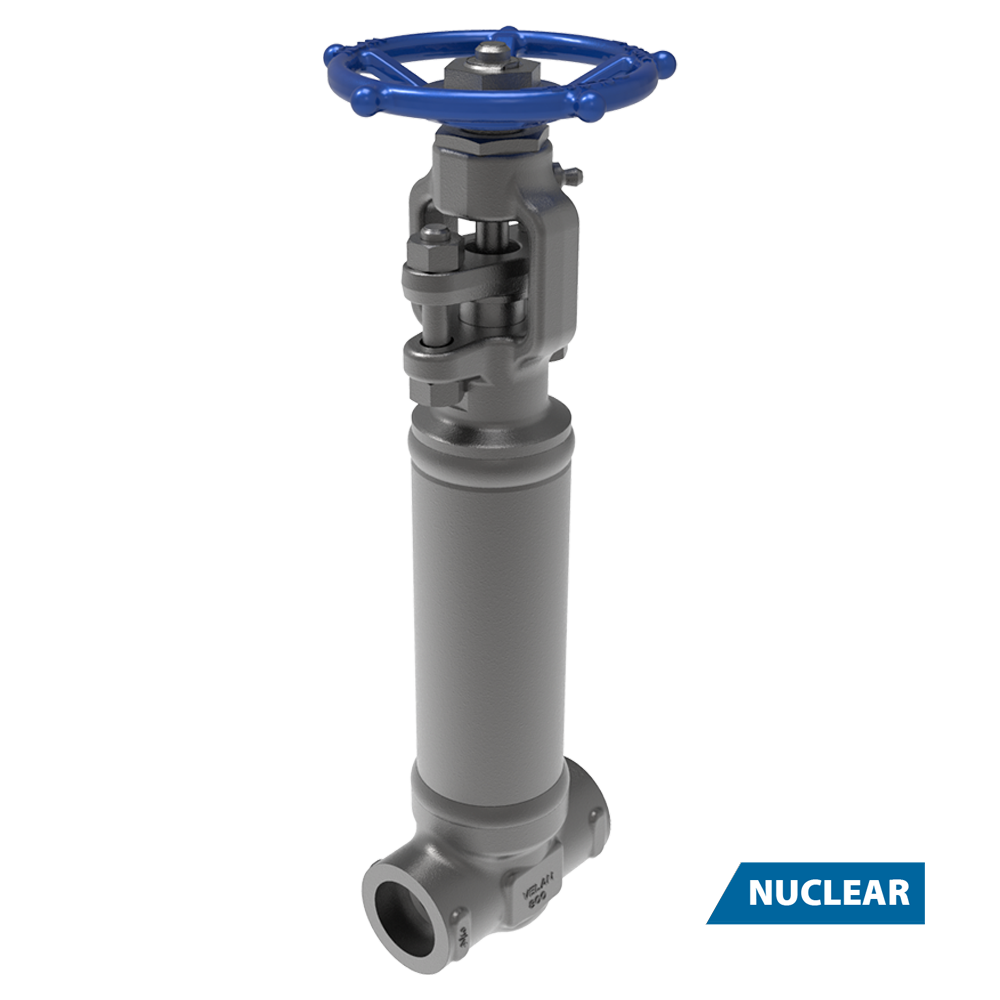

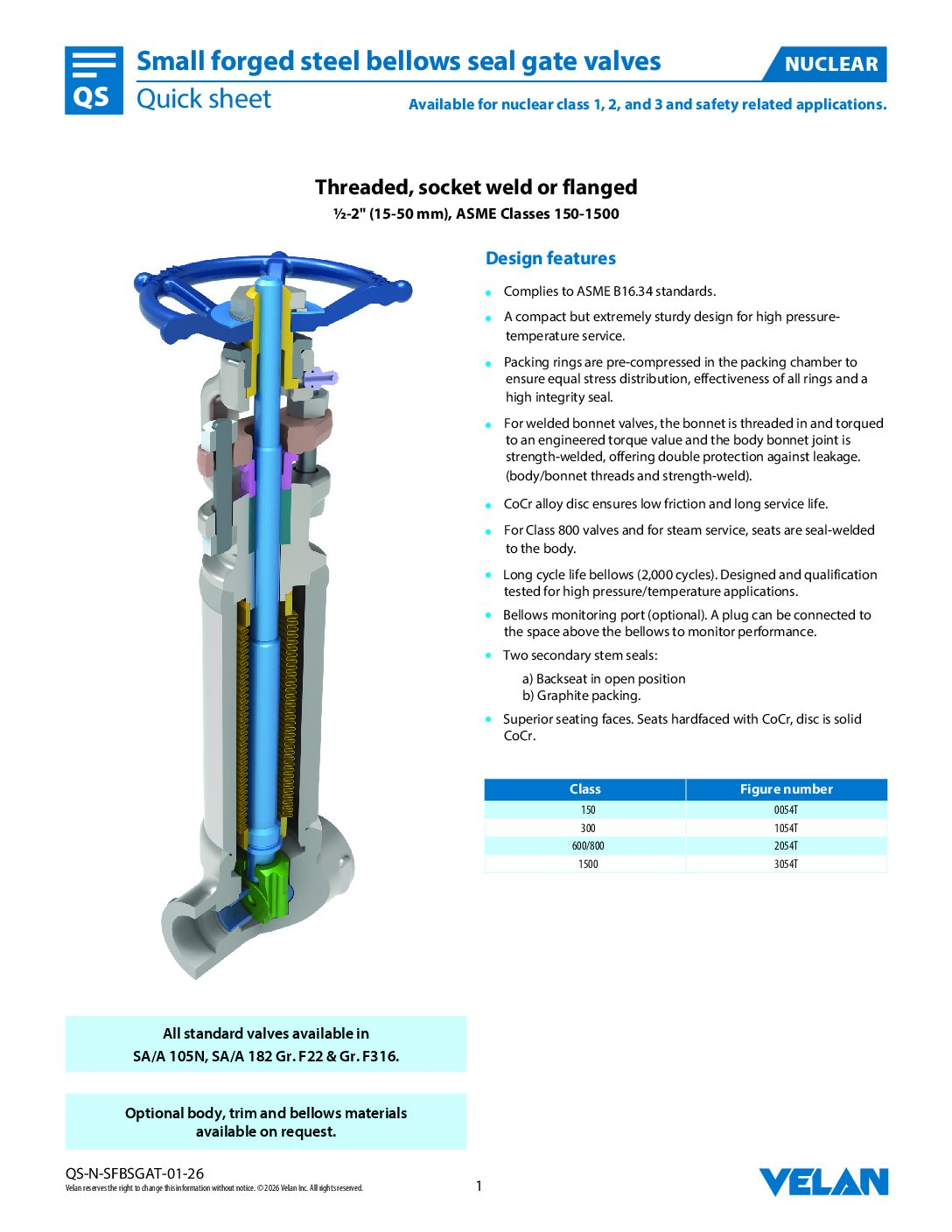

Available for nuclear class 1, 2, and 3 and safety related applications.

- Complies to ASME B16.34 standards.

- A compact but extremely sturdy design for high pressure-temperature service.

- Packing rings are pre-compressed in the packing chamber to ensure equal stress distribution, effectiveness of all rings and a high integrity seal.

- For welded bonnet valves, the bonnet is threaded in and torqued to an engineered torque value and the body bonnet joint is strength-welded, offering double protection against leakage. (body/bonnet threads and strength-weld).

- CoCr alloy disc ensures low friction and long service life.

- For Class 800 valves and for steam service, seats are seal-welded to the body.

- Long cycle life bellows (2,000 cycles). Designed and qualification tested for high pressure/temperature applications.

- Bellows monitoring port (optional). A plug can be connected to the space above the bellows to monitor performance.

- Two secondary stem seals:

a) Backseat in open position

b) Graphite packing. - Superior seating faces. Seats hardfaced with CoCr, disc is solid CoCr.

Détails du produit

| Spécifications | Détail |

|---|---|

| Gamme de tailles | ½-2" (15-50 mm) |

| Classe de pression | ASME Classes 150-1500 |

| Connexions standard | Threaded, socket weld or flanged |

La bibliothèque Velan

Documents connexes

Explorez les ressources et documents connexes, notamment les catalogues et certificats de produits, les manuels de maintenance et bien plus encore.

Explorez toute la littérature

Contactez-nous

Tendez la main

Besoin d’aide ou une question ? L’équipe Velan est là pour vous aider.

« * » indique les champs nécessaires